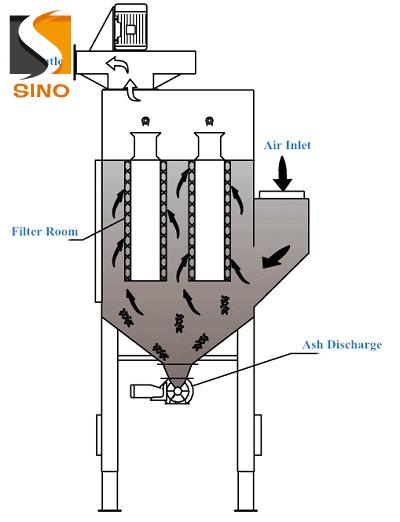

Look at the picture above: Dust-containing air enters the inside of the equipment from the air inlet, large particles of dust fall directly into the ash hopper, and lighter small particles of dust continue to rise to the filter material. After filtering, the dust is blocked to the surface of the filter material, and the clean air penetrates the filter material and is discharged from the equipment through the fan.

Dust-laden gas enters the filter chamber from the air inlet (or bottom opening flange), and coarse particles fall directly into the ash hopper. The dust gas is filtered through the filter bag of the dust collector, and the dust remains on the surface of the filter bag. The clean gas is discharged from the bag's mouth to the air chamber and is released into the atmosphere by the fan.

If the dust on the surface of the filter bag continues to increase, so that the resistance of the filter bag equipment continues to increase the transmission value, the program controller will start to work, open the solenoid valves one by one, and let the compressed air blow out the dust in the filter bag through the nozzle, so that the filter bag suddenly expands. Under the action of the countercurrent air flow, the dust attached to the surface of the filter bag quickly falls off the filter bag, falls into the ash storage, and is discharged through the ash pump valve. After all the filter bags have been purged, the filter bags will resume normal operation.

If the bag filter works normally, the dust gas enters the ash hopper from the air inlet. Due to the rapid expansion of the gas volume, some coarse dust particles fall into the ash storage due to inertia or natural arrangement, and most of the other dust enters the bag with the airflow. After filtering through the filter bag of the filter, the dust particles are stored outside the filter bag, and the gas enters the filter bag from the inside and then is released into the atmosphere at the valve hole of the box body to achieve the purpose of dust removal.

Continuous filtration will also increase the resistance of the dust collector. When the air resistance reaches a certain value, the dust collector sends an instruction to close the airflow, and then the vacuum dust collector regulator sends a signal to the solenoid valve. Through the solenoid valve, the dust inside the bag adopts high-pressure airflow, the filter bag of the dust collector expands and vibrates strongly, and the dust outside the filter bag is shaken to achieve the purpose of dust removal. The device is divided into several boxes, and the processing boxes of the above-mentioned boxes are executed. When a box area is cleaned, another box area can still work normally, which means that the continuous normal operation of the equipment can handle high dust because the cleaning time is very short (only 0.1-0.2 S per spray). After the dust falling in the ash, the hopper accumulates to a certain amount. It is discharged by a manual or electric flapper valve, and then falls into the funnel, and is discharged by the user.

The dust collector has online cleaning and offline maintenance functions.

The control of the dust collector (dust purification control after the bag) is controlled by the DCS and the host computer.

The control of the entire dust removal system meets the operation monitoring and operation requirements and has an offline function.

The overhaul and maintenance work is carried out outside the sedimentation tank without penetrating the inside of the sedimentation tank.

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China