Dust collector is a filter device suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of textile filter cloth or non-woven felt and uses the filter function of the fiber fabric to filter the dusty gas. When the dusty gas enters the bag filter, the dust with large particles and large specific gravity will When the air containing fine dust passes through the filter material, the dust will be blocked and the air will be purified.

It is widely used in electric power, the chemical industry, food, mechanical processing, casting, and other industries. With the tightening of environmental protection policies, more and more people pay attention to its dust removal efficiency and dust removal effect. With the long use time and the aging of the equipment, the dust removal efficiency will decrease, resulting in the emission not meeting the standard. Therefore, it is necessary to do a good job in the inspection and maintenance of the dust collector.

The main maintenance components of the dust collector are the dust collector body and pipeline, dust cleaning system, dust discharge system, control system, and fan.

1. Dust collector body

The box of the bag filter is divided into two parts inside and outside, and the gap of the box is for maintenance.

The main inspection points for external maintenance are paint, rain leakage, bolts, and surrounding sealing conditions. For high-temperature and high-humidity gases, in order to prevent condensation and ensure safety, an insulation layer such as rock wool, glass wool, and polyphenylene is generally provided on the outside.

The main inspection points for internal maintenance are: pay attention to selecting corrosion-resistant coatings and apply them on the parts that are prone to corrosion or have been corroded in time. Under normal circumstances, since most of the purified gases are acidic, epoxy resin-based acid-resistant coatings are often used.

The gap part of the box should also be maintained. The box gaps are generally padded with rubber, rubber pads, asbestos pads, etc. to prevent gas leakage.

2. Pipeline

After the pipes of some dust collectors have been used for a period of time, dust will settle in the pipes. Dust deposits mostly occur at the elbows. When passing through the elbows, the resistance is large and the speed drops, resulting in dust precipitation. The more precipitation, the more it will cause the pipeline to be blocked, resulting in insufficient air volume. Therefore, the cleaning port should be designed in the dust-containing pipeline, and the deposited particle dust should be cleaned regularly. The observation hole and cleaning port are installed on the pipeline. The deposited dust is lifted up manually, and then sucked away with the gravity of the dust removal fan, or the accumulated dust is removed directly from the cleaning port.

The long-term use of the dust removal pipe will wear the pipe wall due to the wear of the dust-containing gas, mainly concentrated in the elbow part of the pipe. The air leakage in the worn place will reduce the air suction volume and wind pressure at the dust collection port, which will affect the dust collection effect. It even causes dust to settle in the pipe, so the worn pipe wall should be repaired in time.

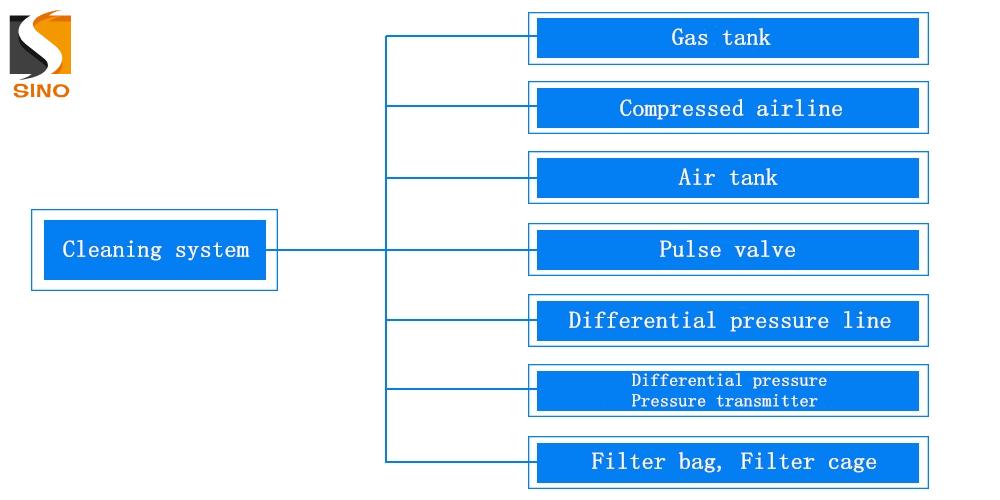

3. Dust cleaning system

The parts that need to be overhauled in the cleaning system include the air tank, compressed air pipeline, pulse valve, differential pressure pipeline, differential pressure, pressure transmitter, filter bag, and filter cage.

The air tank is a pressure vessel and needs to be inspected every year.

Check the compressed air pipeline for leaks.

Whether the pressure gauge, safety valve, and drain valve are normal

Whether the pulse valve is working normally and whether there is any damage to the diaphragm.

Whether the differential pressure pipe is blocked.

Are the instruments working properly?

According to the dust concentration meter, single-chamber differential pressure transmitter and shutdown, open the upper cover, and pull out the filter bag to check whether the filter bag and cage are damaged or invalid.

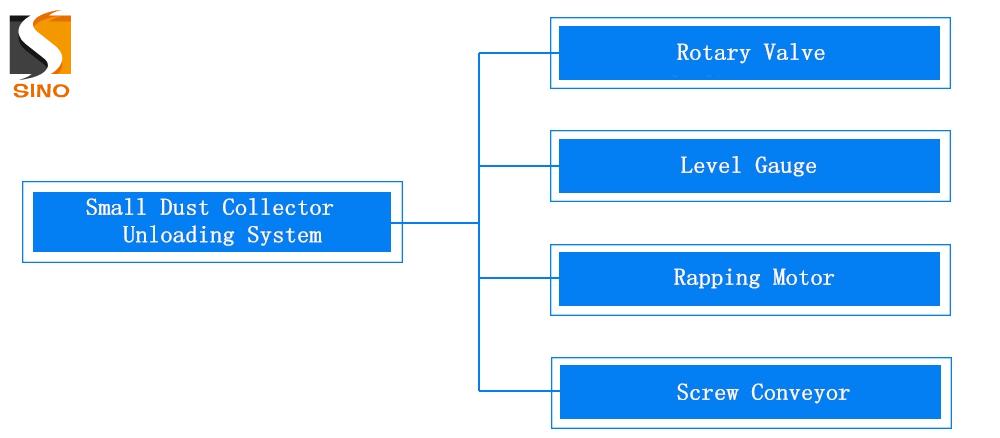

4. Small dust collector unloading system

The parts that need to be overhauled in the ash unloading system of the small dust collector are composed of an unloader, material level gauge, vibrating motor, and screw conveyor.

The lubricating points of the mechanical transmission parts should be oiled and lubricated according to the frequency requirements. The operating time is 8 hours. If the daily operating time exceeds 8 hours, the maintenance and inspection cycle must be shortened. The types of lubricating oil are distinguished, and each oil filling port must be sealed well to prevent dust from entering and contaminating the lubricating oil and generating impurities;

Whether the sensor positioning of the material level gauge is accurate, and whether there are false alarms or alarm failures.

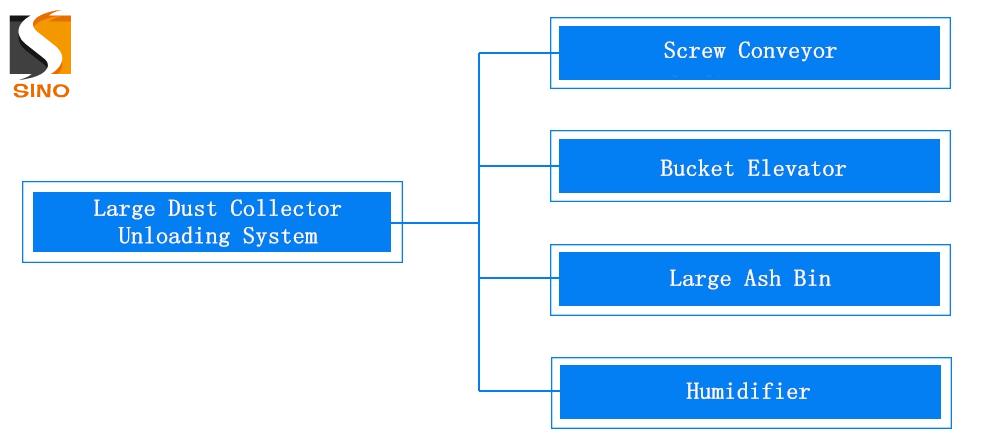

5. Large dust collector unloading system

The parts that need to be overhauled in the large-scale dust removal and ash unloading system include the screw conveyor, bucket elevator, large ash bin (dust collector on the top of the bin, material level gauge, vibrating motor), and humidifier (to prevent secondary dust).

The lubricating points of the mechanical transmission parts should be oiled and lubricated according to the frequency requirements. The operating time is 8 hours. If the daily operating time exceeds 8 hours, the maintenance and inspection cycle must be shortened. The types of lubricating oil are distinguished, and each oil filling port must be sealed well to prevent dust from entering and contaminating the lubricating oil and producing impurities

Whether the sensor positioning of the material level gauge is accurate, and whether there are false alarms or alarm failures.

6. Fan

Commonly used dust removal fans are direct-coupled V-belt drive, and coupling driven.

For direct-coupled fans, check the wear of the coupling and elastic pins to prevent the vibration of the transmission shaft caused by wear and affect the service life of the bearings. Keep the oil level in the bearing box so that the bearings are fully lubricated

V-belt-driven fans focus on checking the tightness and wear of the belt to prevent the fan from losing speed due to the V-belt being too loose, which will affect the air volume and air pressure

Coupling type fan elastic ring The rubber elastic ring of the pin coupling, the rubber joint of the elastic pin coupling, and the elastic diaphragm of the diaphragm coupling are all elastic elements, which can compensate for the relative displacement of the axis. Due to repeated start-up shocks, long-term vibration wear, corrosion, and aging effects, elastic elements will fail. Therefore, it must be inspected regularly every year. If the rubber components are aging and worn, and the elastic diaphragm is lodging or defective, it must be replaced in time

In addition, it is also necessary to check whether the impeller and bearing of the fan are worn. Generally, the impeller will not wear out, but if the dust bag is damaged, the dusty gas will be discharged with the induced draft fan, and the impeller will be worn, resulting in a small air volume. Impeller wears When the air volume of the fan fails to meet the usage requirements, the hidden danger of impeller wear should be eliminated in time and the impeller should be replaced.

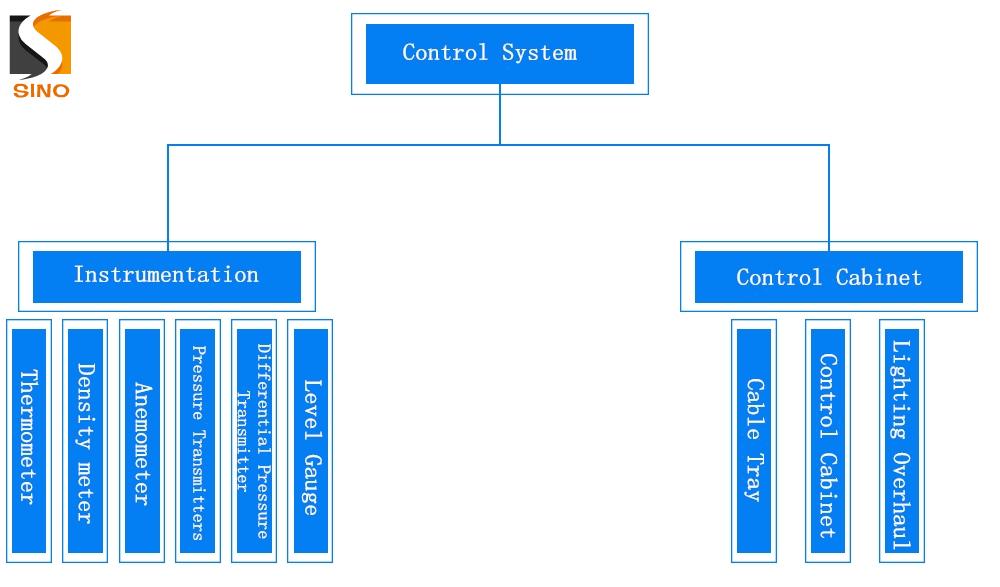

7. Control system

Conduct regular inspections on the electric control cabinet, and deal with problems in a timely manner.

Regularly clean the high and low-voltage power distribution cabinets to keep the power distribution cabinets clean and well-insulated.

Regularly calibrate the testing instruments to ensure accurate measurement of the testing instruments.

Conduct regular functional tests on interlocking, protection, and alarm devices to ensure that the interlock, protection, and alarm are in an effective and reliable state.

Regularly test the local operation and emergency operation functions to ensure that the functions are effective and reliable.

Replace damaged instruments, operation buttons, switches, and indicator lights in time, and do not make the equipment work with defects.

Do not cancel the interlock protection function of the equipment.

Contact: Jane

Phone: +86-136 0202 1569

E-mail: info@sinobaghouse.com

Add: No.14 Building, Jingjin Shishang Plaza, Wuqing District, Tianjin, China